Rob Mays

For the last 35 years or so I have worked in construction. The last 20 years as a freelance construction manager. I have my own company for that called Rmaysing Design and Build Ltd. When I got my first job after I left school in the Stock Exchange, I saved £750 which was a lot of money then and brought my first set of tools. Then I started to get work as a carpenter. I never did an apprentiship or had any qualifications other than my ‘O’ levels when I left school. So most of the things I have done through my life have been self taught.

Through this time I have always kept a love of wood and the sea. I have a wood-turning lathe and about 3 years ago started to carve spoons as well. Seeing others turn items and carve spoons inspired me to develop and grow Rmaysing Things. Recently, I started to get interested in making jewelry for ladies and men. This is totaly new for me but was born from always collecting things on the beach and wondering what I could do with them. I also now create wooden rings for people. I currently still work in construction but aim to grow Rmaysing Things into another income stream.

I do not mass-produce my items. I may only make one or a few, so when they’re gone, that’s it. Sometimes I will make variations of the original. With the jewellery especially because I use natural materials they are unique anyway and cannot be repeated.

Follow me on social media to see what I am making and how I do it. Click the Link Here to chose where you want to go next.

Robert Mays – From Building to making.

My name is Robert Mays, but most people call me Rob. Here I just wanted to give you a brief history of my life in construction and how I went from that to building the idea of Rmaysing Things.

Early Years.

I was born in Bromley in Kent and was brought up in Hayes. We lived with my Grandad. In our garden we had a shed and Grandad had loads of old tools in there which I used to love using. I have always loved wood and woodwork.

School

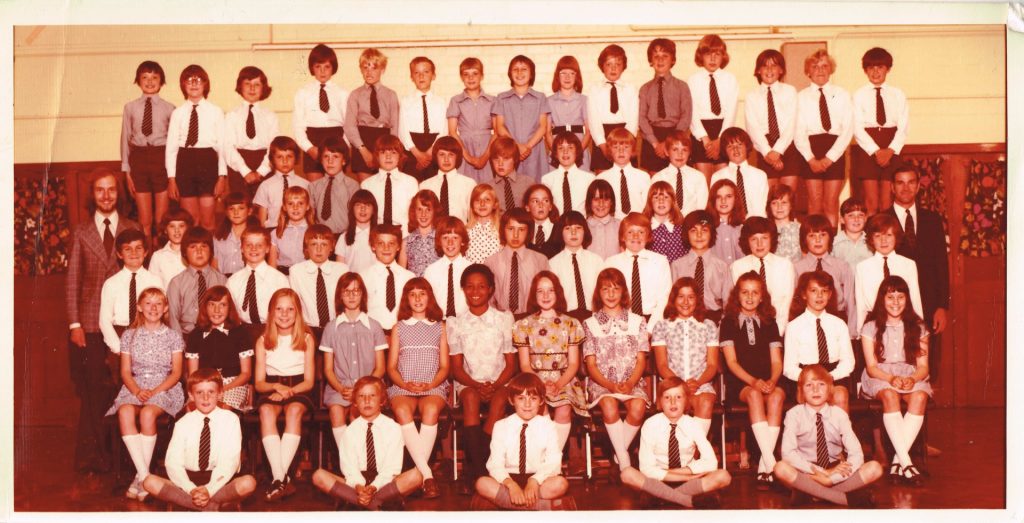

I went to Hayes Secondary School. I enjoyed school and we used to do woodwork, metalwork, and technical drawing. When we had to choose our subjects, they insisted that if you did woodwork you had to do technical drawing. As a result, there were only five people in our woodwork class which was great as we learnt a lot more

I left secondary school with an A grade O level in woodwork and a B grade in technical drawing amongst others.

For that, we had to make something that they specified, show how we developed the idea, and then create full working drawings for it.

My first Job.

My first job had nothing to do with construction. It was on the Stock Exchange. I didn’t start doing building work until I was in my early 20s. When I left that job, I had saved some money and took about £750p and went out and brought my first set of carpentry tools, but I had no site experience at all. That was how I started. After a while I left the stock exchange and started working for myself. Initially I thought I could build a business making children’s wooden toys from our spare room at home. I’ve always had that desire to create and make things.

My first real site work.

When I was about 23, I got a chance to work on a big site. A lot of us didn’t drive so we used to “live in”. We were working on the car park and roadway for a large assembly hall. I started out as a labourer, barrowing sand. I worked my way up and eventually I could start laying the blocks. Here is a picture of me working there.

After that I started working with a friend of mine who set up a company and we used to do block paving in and around the Caterham area where he lived. Unfortunately, I lived in Brixton and still did not drive. So, I had to get the 59 bus there and back.

Driving.

He used to drive an old Morris Marina van. He let me learn to drive in it, even in the snow, I remember it had no heater. Eventually, I passed my test, I think I must have been about 23 or 24. John had an old Mini at his house and he offered to sell it to me. It needed a lot of work doing to it. It was a B reg 1964 car, so it was the same age as me. We resprayed it in its original colour, Antelope Green. Strange the things you remember. Driving gave me lots more freedom as far as work was concerned.

Working on the coast.

I moved to Hastings where I used to work for different people doing building work. Small jobs mainly, window repairs, small extensions, that kind of thing. I had also started to do more building projects for a charitable organization. These projects were called Quick Builds and they would take me to many different places where they would build assembly halls, quickly, very quickly. These buildings were designed to hold 100 people or so. Typically, they would take 3 or 4 days. Sometimes though they would be done in two days. They were full builds from the DPC level up. They would have fully fitted toilets, kitchen, and carpets and be fully decorated by the end of it. Some were all timber and some would have a brick outer skin. I would do carpentry on these jobs and or block paving to. This would take an enormous amount of organisation not just of people but materials and welfare too.

Changing careers and moving again.

When I was about 29, I had a mate who started selling insurance for the Coop. He was doing well at it and I decided to give it a go too. By now I had moved back to London. I was a rubbish salesman though and soon realised this was a big mistake for me. As soon as I could, I got back into building work.

I got some work with a guy called James, who I was introduced to. He had a team of 4 guys, and we used to do extensions and general building. But it was regular, steady work. By then I was mainly doing carpentry. But because we were a small team, we used to get involved in other trades as well, apart from electrics, which was too dangerous for me. At about the same time another friend of mine got me into woodturning. He had an old lathe that he sold me. It is a Woodmiser 14/60. I still have it today and use it. But where I kept moving around for so long I often was unable to do anything with it for a long time.

A band, getting married and site management.

By now, I was about 33 and living in west London. I got a job working for a company called Craftwork. I met a man there called John and we became friends. Him and his wife had a band, playing in pubs and social clubs. I had a bongo, which I brought on holiday in Jamaica but I wasn’t very good at playing it. For some reason, John and Jane thought it would be great if I joined their band. That was when I met Charlene, Janes cousin. She was coming down for the weekend and we would be playing in a British Legion club in Strawberry Hill. To cut a long story short we met on the 2nd of March 2002, we were engaged on the 15th of August and married on the 7th of January 2003. My son was born in January 2007.

Craftwork changed hands I went back to work for James. His company was getting quite big and we were doing more and more projects that were getting bigger. One house we worked on was a house that was built in the late 1400s in Essex and was brought, dismantled, moved, and rebuilt in Kingston in the early 1900s. It was a timber frame house and had lots of oak paneling inside. When the inside work was ending, I was asked to oversee the outside work. That was the first time I got asked to work managing other trades and have never looked back really from that time. Next, I was asked to fill in on a job where the site agent was going on holiday for a couple of weeks. I got on so well with the client that they asked if I would stay on and complete the house and the other guy got moved to another job.

This is the first house that I built from scratch. It was also how I got into drawing, as in CAD work. A lot of work that we did was design and build. This house had a big conservatory at the rear of the house. But it was unclear from the details we had how to construct it. We wanted to send the drawings out to be quoted and manufactured, but this would not be possible with the details we had. So, I started to draw the conservatory on a computer program I brought from a shop. We had it successfully manufactured. Then I started on other parts of the house like the front door. From there I have used it to do drawings on lots of different projects that I have been a part of. I have upgraded over the years to the best level I can get so I can do more interesting things. It also does 3D models which is great if you are trying to work out how something will look or work.

I have built a lot of houses since then. Mainly in this high-end sector of the market.

Many of the houses have had:

-

- Basements

-

-

- Swimming pools.

-

- Gyms

-

- Cinema rooms

-

- Controlled lighting such as Lutron.

-

- Air conditioning

-

- Stone floors and walls.

Some others such as the Kingston Hill refurb and The Langley Hotel have been listed so attention to detail and trying to preserve what remained were high priorities.

I have also done some social housing. Most of the work has been for developers though. For most of the time, I have been self-employed as a sole trader and then in more recent times, I started my company Rmaysing Design and Build Ltd which is what I trade under now.

If you click this link Project tab you can see a lot of the other projects that I have managed since that time.

Today I still work in construction and I still enjoy it. But I also have a little dream of building up an altogether different kind of business.

Following a dream.

My wife and I have always wanted to do something together, something where we can spend more time together doing things we love. I like construction and it is a good job. I’m 60 and working on the tools for me is not an option as I’ve got tennis elbow and my knees are bad from lots of block paving. I’m like the song, Three Wheels on My Wagon”, I’m still rolling along but bits are dropping off. Site management is a big responsibility. Over the years it has not got any easier either. I have a black CSCS card and an NVQ level 6 in site management. As I get older though I would rather spend more time with my family and do more of the things l like.

I want to do things with my life, with my wife and family. For many years we have looked at ways we can spend more time together rather than being in the rat race. The urge if you like to make things and try to sell them has been with me for a long time. But I had no clue how to go about it. In the last 5 years or so I have invested in various courses where I have learned new skills including how to shoot videos, edit and publish them, and to market products online. As well as building websites such as this one. I’m not an expert, but it has given me the tools and the confidence to move forward so that instead of just dreaming about my dream, I can start living it and making it come true.

Social Media Links.

I also started my own YouTube Channel, Rmaysing Things. I learnt how to film and edit the videos and also how to build my channel and set up the art work and logo. I also started to get into spoon carving as well as the wood turning. So I have a Facebook page and and Instagram account but they are mainly for things that I enjoy doing such as woodwork, fishing, kayaking and messing about with my son.

A coconut spoon I helped my son to make.

For me making things is about being unique and individual. I don’t want to be a human production line churning out the same stuff over and over.

When I make things they are ideas that I have seen or thought about. They grow and develop as time goes on.

Also because I use natural materials to make things with they are all individual and often unique, true one-offs. Sometimes they are similar but they are never the same. So you are always getting something unique and handmade.

For some of the jewelry pieces that I make I find most of the materials on the beaches that we go to on holiday as a family. That in itself limits what I can make in terms of quantity.

As an example I recently started to make “bentwood” rings. These are rings made from wood veneer and glued together and finished with super glue. There are a lot of people who make these. So there is not much value in being the same as all of them. But in the beginning I wanted to know if I could do it. But then I started to experiment with them.

This is an oak ring. I have ebonized it, which is an old fashioned method of making oak go dark. Then I sanded it back and added gold gilt cream to give it this effect. I have looked on the internet and I cannot find any other rings that are much like it, which is good.

I wondered what else I could do. I noticed that I could not find on the internet any wooden rings with stone cabochons on them. This is my first attempt to make one with a piece of red Carnelion on it. Now I have some other stones on order and I will be making more of them and adding them to my shop.

That gives you an idea of the process. Sometimes it can take a while to get the right finish or design. I always like to wear something that I am going to make for other people before I put it on my shop. That way I know if it will be any good. For example when I first started I made a whale tail pendent for myself. I put it on a leather necklace. But over the summer where it was really hot the leather deteriorated and eventually fell apart. So now I use waxed cotton, which is much more durable and so far after well over a year it is totaly fine and show no site of wearing out or failing. That’s important to me, I want people to be confident in what they are buying from me.